Yaskawa ArcWorld 2000 workcell adapts to changing production demands

July 8, 2016

By Manufacturing AUTOMATION

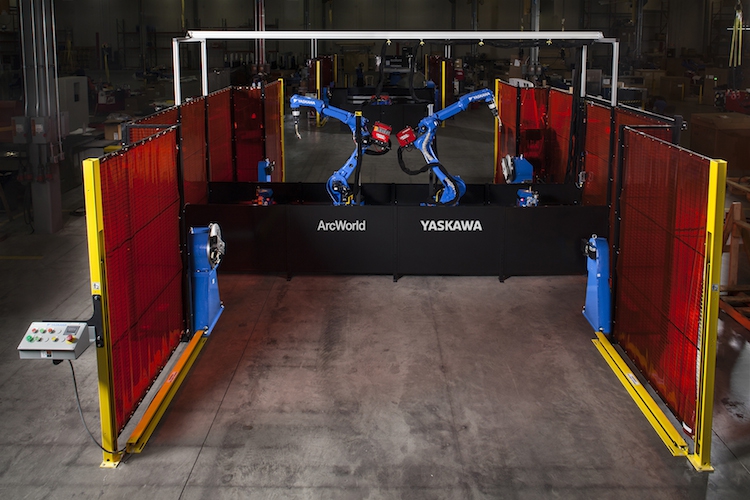

Jul. 8, 2016 – Yaskawa Motoman describes its ArcWorld 2000 welding workcell as a modular solution specifically designed for robotic welding of large workpieces.

The workcell is adaptable to changing production demands; it can be scaled from a single-station layout with a reduced floorspace footprint to a two-robot dual station configuration. Suitable for low- to medium-volume manufacturers with a medium to high mix of parts, the workcell promises to be able to handle parts up to 5 meters in width and payloads up to 6,300 kg. The workcell is configured with one or two six-axis Yaskawa welding robots directed by the DX200 controller with menu-driven arc welding application software, an integrated welding package (power source, wire feeder and welding torch), positioner(s), operator interface and safety barriers, says the company. Two station layouts can be configured with a “blank station,” which Yaskawa says will allow end-user supplied equipment to be installed, and each station can have a different positioner. In dual robot installations, the second robot controller can be a dual-robot control type module (DRC). Torch cleaners or tip-changing stations are installed in a fenced centre zone, providing operator access to stations during robot maintenance.

Advertisement

- Baldor’s Fort Smith employees achieve Arkansas state safety record

- Omron G9SE safety relay promises to simplify troubleshooting