Pilz launches field-level safety devices with I/O system PSSuniversal 2

November 5, 2018

By Manufacturing AUTOMATION

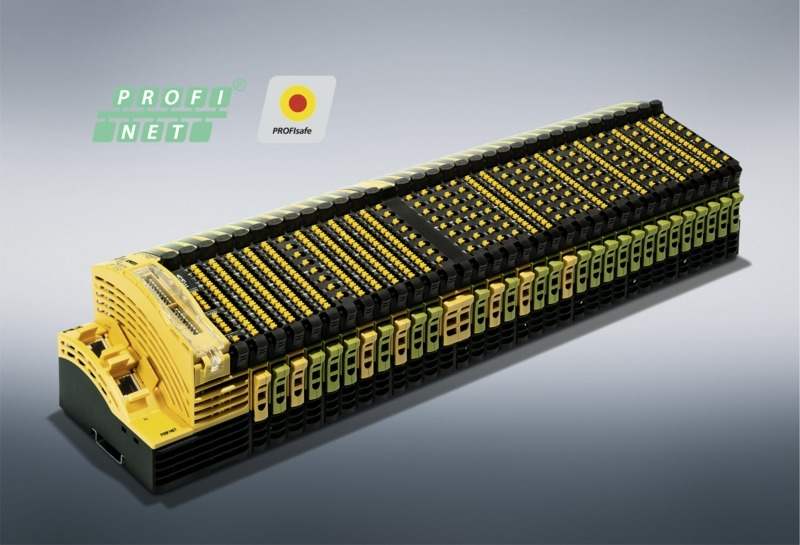

November 5, 2018 – Pilz is launching a new generation of field-level devices for safety and automation with the decentralized I/O system PSSuniversal 2, which consists of the PROFINET communication module and a selection of I/O modules.

The new three-part system design significantly reduces the work involved in service and maintenance – diagnostics can be performed with extreme precision in the remote I/O system, enabling errors to be located and rectified quickly. Modules can be hot-swapped. As a result, the head module can be swapped without having to reconfigure.

It is no longer necessary to completely dismantle the system to swap the backplane. Users can build the system structure quickly on screen via a drag-and-drop configuration tool called PASconfig.

PSSuniversal 2 processes both safety-related and non-safety-related control signals – safety and automation are physically mixed but logically separated, so they operate without feedback. In its basic function, the head module communicates with PROFINET/PROFIsafe. At the next level, a communication module with Ethernet IP / CIP Safety interface and other I/O modules are added to the system.

Users can connect the remote I/Os in PSSuniversal 2 to higher-level control systems via common industrial communication protocols. The remote system provides benefits in any situation where plants are distributed over a wide area.

Advertisement

- Rockwell Automation announces senior leadership transitions

- Irving Pulp & Paper to pay $3.5M for dumping charges