Manufacturers share top technologies on their automation wish list in latest MA poll

March 6, 2024

By

Sukanya Ray Ghosh

Manufacturers have been aware of the continuous advances in Industry 4.0 technologies for years now. While some manufacturers have already implemented some form of automation in their facilities, others are considering it in the near future.

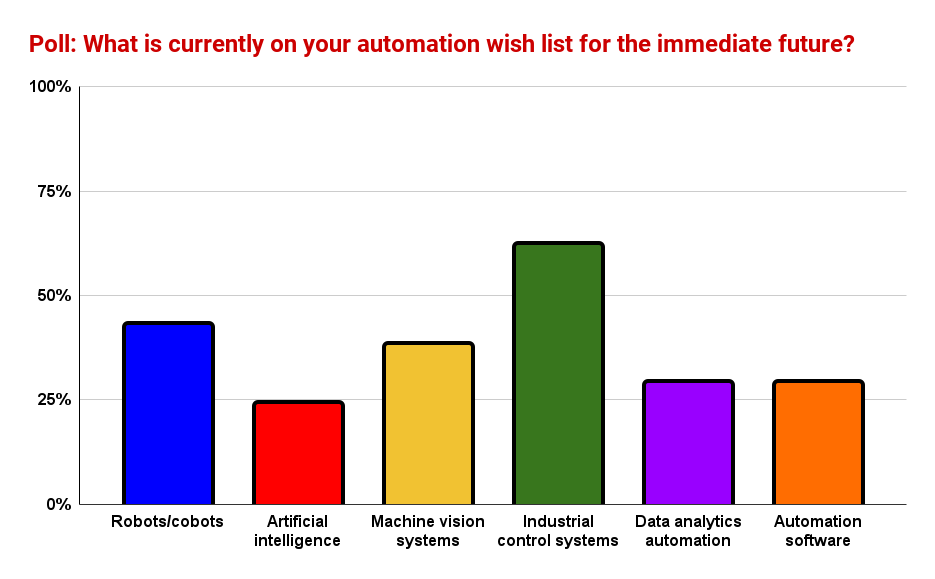

In the latest Manufacturing AUTOMATION poll, manufacturers were asked to share what technologies were on their immediate automation wish list. With the option to select multiple responses, the poll yielded some interesting results that are quite in tune with the current industry trends.

Industrial control systems are at the top of the wish list for 59 percent of the respondents. Industrial control systems are the integrated hardware and software systems used to control and monitor processes within the facilities. These systems play a crucial role in managing and optimizing manufacturing operations, ensuring efficiency, reliability and safety. Key technlogies include PLCs, SCADA systems, distributed control systems, HMIs, sensors and actuators, communication networks and safety systems, among other things.

Not surprsingly, 45 percent respondents shared that robots and cobots were on their immediate automation wish list. Lack of skilled labour is one of the top reasons manufacturers seek out robots and cobots to perform repititive tasks, allowing them to free up plant personnel for more skilled tasks. As advances in technology have made it easier to deploy robots of all types, shapes and sizes, it is one of the most sought-after automation solutions.

Manufacturers focus heavily on ensuring that they are producing quality products seamlessly. If there are defects in the end products, they prefer to catch them as early as possible. Machine vision systems can offer the extra “eyes” needed to detect and flag issues 24/7. These systems provide high levels of precision and accuracy in measurements and inspections, surpassing the capabilities of manual inspection. The poll results indicate that 38 percent of the respondents wish to implement machine vision systems in the near future.

Artificial intelligence is one of the most trending topics being discussed in the industry this year. Manufacturers are keen to explore how AI can contribute to enhanced efficiency, competitiveness and innovation for their businesses. Industry experts agree that in the near future, generatve AI will possibly change human-machine interactions on the plant floors. In the poll, 34 percent of the respondents indicated that AI is on their automation wishlist.

Thirty-four percent of the respondents also indicated that automation software is at the top of their automation implementation plan. Manufacturing facilities use a variety of software applications to streamline processes and manage different aspects of their operations. The specific types of software can vary depending on the size of the facility and the nature of the manufacturing processes. Enterprise resource planning (ERP) software, manufacturing execution system (MES), product lifecycle management (PLM) software, supply chain management (SCM) software, software for warehouse mangaement and quality management are some of the many options available to manuafcturers to manage the different moving parts in their processes.

All automation technologies on the plant floor continuously collect data. The right data can equip manufacturers with the foresight to predict outcomes, streamiline their processes, maximize productivity and improve overall efficiencies throughout the manufacturing business. However, not all data is relevant. Having systems in place to analyse the data is key to leveraging it appropriately. It is therefore not surprising that 31 percent of the respondents shared that they wish to implement automation for data analytics.

Advertisement

- Automate 2024 to highlight women leaders in automation

- Universal Robots appoints new vice-president of service and aftermarket