New robotic washing system for aerospace manufacturing

June 11, 2021

By Manufacturing AUTOMATION

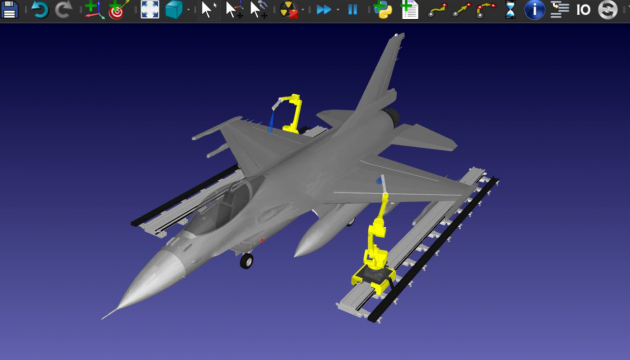

Software developer RoboDK and automation specialist Wilder Systems develop "drive-through" washing system

Photo: RoboDK

Photo: RoboDK RoboDK, a Montreal-based software company, has enabled automation solutions provider Wilder Systems to develop a robotic “drive-through” washing system for aircraft.

In May 2021, Wilder Systems released the new solution specially designed to automate the washing process. The programming interface is provided by RoboDK and allows novice users to program the robotic system themselves.

The system reduces the task time by 95 per cent and eliminates manual washing. By using the RoboDK programming software, aerospace manufacturers can program the task without previous robotic experience.

Eliminating manual washing

Regular washing is a critical task in aerospace manufacturing. It helps to reduce corrosion, improving the life and safety of the aircraft. However, manual washing is a dangerous and labour-intensive task.

The conventional method of airplane washing involves using sponges, brooms, rags and ladders. A team of four mechanics would usually take four hours to wash a plane manually, taking a total of 16 person-hours.

With all the associated tasks, the entire washing operation often takes an entire day. During this time, the mechanics are unavailable to perform higher-value work and the aircraft is out of service. On top of this, airplane washing is a dangerous task. Mechanics work from the top of tall, wet and slippery ladders, which can lead to injury.

Wilder Systems, based in Austin, Tex., specializes in creating robotic solutions for aerospace manufacturers. With the new system, the company automated the entire washing cycle, which is now completed in 52 minutes.

How the system works

The robotic system uses a combination of various off-the-shelf hardware and software components that the team at Wilder Systems integrated into a self-contained washing cell.

The core hardware components are two FANUC six-axis industrial robots, a programmable logic controller, and hydraulic pump systems for the foaming and rinsing sprayers.

The core software components are RoboDK and Autodesk Fusion 360 for CAD/CAM, which integrates directly with RoboDK through a native plugin.

Alejandro Rengel was the main programmer of the project. He explains that the RoboDK software led to the development.

“Using CAD-To-Path strategies, we were able to generate robot paths that were adaptive and error-proof,” Rengel says.

Jérémy Brouillard, RoboDK’s lead product manager, explains that the project employs some unique features that the software provides.

“Many RoboDK features were used in this single project,” says Brouillard. “Wilder Systems used the ‘teach target on surface’ feature to program the first half of the plane.

“They defined the right washing angles and simply clicked on the plate surface to define the robot trajectories. To finish it up, they saved half the work by using RoboDK’s Python API to mirror the programs for the second half of the plane.”

Wilder Systems plans to use this same robotic platform for other aircraft maintenance tasks including depainting and repainting, panel drilling and non-destructive inspection.

The company also plans to further improve the agility of the current system by mounting it into a mobile, autonomous platform so they can perform operations throughout the flight line.

Advertisement

- Feds invest $625K in cabinetmaker for new finishing line

- Fortinet debuts two new services as part of security offering