API releases new robot performance measurement and calibration solution

November 12, 2018

By Manufacturing AUTOMATION

November 12, 2018 – Laser measurement technology company Automation Precision, Inc. (API) has launched a laser tracker–based industrial robot performance and calibration tool to verify robot accuracy.

The Robot Measurement Solution (RMS) allows for on-site, in-situ robot performance verification and enhanced robot calibration. The company says that industrial robots calibrated with the RMS system during extensive development testing have exhibited an improvement in positioning accuracy of up to 12 times.

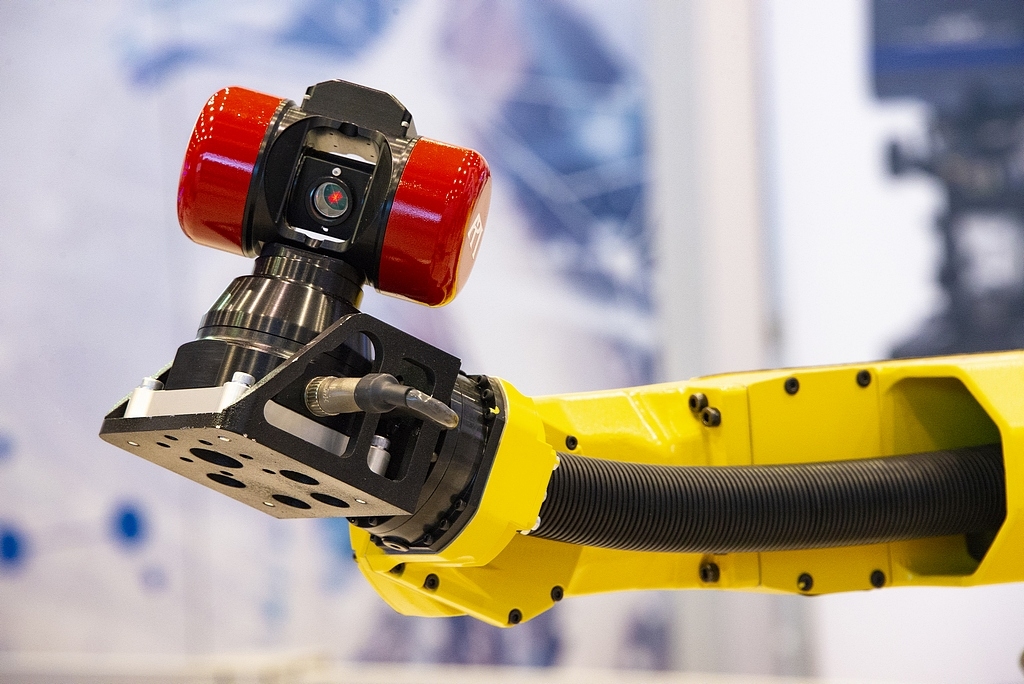

The RMS tool includes API’s 6 DoF (Degrees of Freedom) RADIAN Laser Tracker complimented by the API Smart Track Sensor, which mounts directly to the robot’s end effector, allowing the laser tracker to dynamically collect X, Y, Z, and I, J, K data for each robot position in space accurately and automatically.

The robot is automatically driven to discrete positions using API’s Robot Performance Measurement (RPM) software providing fully automated measurements and data acquisition, and allows customization of the actual workspace under calibration. Up to 30 robot parameters can be calibrated in a completely automated run-time.

RMS can be supplied as a module or combined Robot Calibration (RoboCal) and Robot Path Plan Enhancement (PPE) module. RoboCal offers both DH kinematic model and a volumetric error compensation model to update robot accuracy using collected data. Once a robot has been calibrated, existing robot path programs can be automatically updated driving the robot to its corrected calibrated positions.

RMS provides access to an extensive library of industrial robots from over 30 manufacturers.

Advertisement

- Manufacturing companies land on Canada’s Top 100 Employers list

- igus introduces lightweight delta robot that can carry up to five kilograms