Succeeding with Industry 4.0: Understanding the whole elephant

August 19, 2020

By Julie Fraser

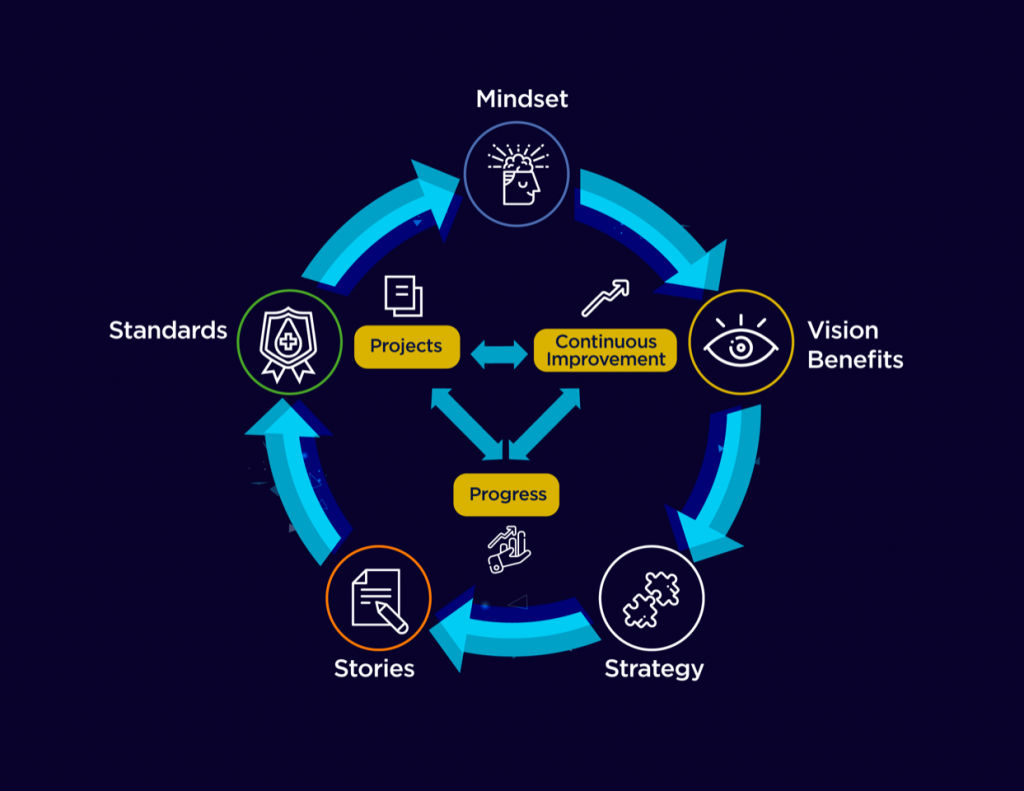

With the right narrative by level and function, the whole company, whether top-level management or shop-floor workers, can engage with strategy and participate in setting the standards required to make Industry 4.0 a reality

Photo: Tech Clarity

Photo: Tech Clarity The majority of industrial Internet of Things (IIoT) projects are either not meeting their objectives or failing outright. Why is this happening? The answer links to whether the right foundation is in place for success – and this is where businesses need to understand the whole Industry 4.0 (I4.0) elephant.

I4.0, or smart manufacturing, has the potential to deliver huge benefits to manufacturers of sophisticated products. It offers increased efficiency, lower cost, higher quality, insight for continuous process improvements, increased productivity and the ability to deliver customized or small batch orders efficiently.

Any company would want to see at least a few of these benefits for their operations. The question is, however, how to get there?

Most organizations are dipping their toe into the I4.0 pool with a proof of concept or small-scale project. The problem is that these trials are not producing the level of benefits this new revolution in manufacturing technology can offer.

Even if a test project is successful, if it does not fit into the overall business strategy, a wider rollout is doomed to fail or, at the very least, not deliver full business value. Businesses are falling into several pitfalls because the very essence of I4.0 requires a wider view.

As the vice-president of research for manufacturing software of Tech Clarity, an independent research firm, I recently authored an e-book to help companies avoid I4.0 initiatives falling off the rails. Here’s an excerpt:

“Research has indicated that up to half of IIoT projects fail or are not meeting expectations. It is not that these projects are bad, but they need a strategy behind them. Many failures come from inadequate planning and a lack of enterprise-wide understanding and buy-in. We are in a new era for manufacturing, and to succeed, digital transformation needs to be at the heart of a company’s strategy.”

Pillars for success

First, for a small I4.0 project to be successful, it must be a high-value proposition with the right foundation to deliver the overall vision. The technology selected needs to be usable and economically scalable for successful rollout.

Second is a change of mindset. Manufacturers have historically introduced iterative improvements through lean manufacturing strategies. Typically in lean, employees who are specialists in their area are empowered to make changes to improve performance in their area.

I4.0 requires a different approach, one that considers what is best for the entire company rather than only an individual process or workstation. To this end, people to think globally, even if they are acting locally. Beyond making decisions on data currently available, they must also consider how to get better data to improve decision making in the future.

A company strategy to embrace I4.0

Without the right strategy and a shared vision, disconnected projects will not necessarily drive towards the goals of the company. The success of I4.0 projects relies on having the right mindset within the business.

I4.0 is an enterprise transformation and, as such, it demands a strategy to get the business from where it is today to its envisioned future state. Thus, beyond installing smart technology, companies must focus on changing hearts and minds of the people within the company to embrace this revolution.

The company strategy should have a strong enough purpose to generate passion in employees. It needs to make purpose and priorities crystal clear, so decisions taken locally work with the vision for the whole enterprise. The strategy itself also needs to be continuously improving as the market develops, and as the business grows and changes.

I4.0 comes with huge benefits, which means companies who ignore it could be left behind by the competition.

Yet, we must recognize that it requires an enormous change in manufacturing operations. For this transformation to be successful, employees must be diligent, disciplined, and open-minded to acknowledge when something needs to be different.

Leaders need to formulate a strategy and then communicate across different branches within the business so each person can understand what it means and what part they need to play.

With the right narrative by level and function, the whole company, whether top-level management or shop-floor workers, can engage with the strategy and participate in setting the standards required to make I4.0 a reality. The passion to drive the project forward will come from everywhere, creating an approach that is much more likely to succeed.

Embed I4.0 practices

Each I4.0 project should deliver benefits that help the company, its employees, and its customers.

Many companies understand that IIoT and I4.0 are important if not critical for the future of their operations. Yet they are struggling with how to move forward.

One of the main reasons initial I4.0 trials are failing is that they lack an overriding, enterprise-wide strategy. Without a clear vision and strategy, the results of small I4.0 projects will only show costs and not benefits.

It’s crucial to paint a whole picture where I4.0 brings together data from across the entire value chain. The resulting holistic view of operations can lead to better understanding of interdependencies and clear indication of where to make process improvements to deliver the most benefits.

The very essence of I4.0 is to have a factory that learns and improves, enabling new business competitiveness. I4.0 must be embedded within the company-wide vision for even small, trial IIoT and related projects to have a good chance for success.

That is not to say it does not make sense to carry out trials. However, finding the right small project with big impact requires a view of where likely benefits are going to be. Benefits are based on understanding where the whole company is trying to go.

In this way, success lies with “understanding the whole elephant,” and not trying to examine just one part: For the elephant to work, it needs a trunk, a tail and everything in between. If we just look at the tail, we do not have the vision of how magnificent the elephant is.

Julie Fraser is vice-president research, manufacturing software at Tech-Clarity, an independent research firm.

Advertisement

- Ontario Teachers’ invests in warehouse robotics firm inspired by ant colonies

- CenterLine releases SoftMount Gun for projection welding