The Blue Revolution: Eco-manufacturing with blue lasers – The new industry standard?

July 25, 2023

By Tomorrow's System

Brought to you by Tomorrow's System

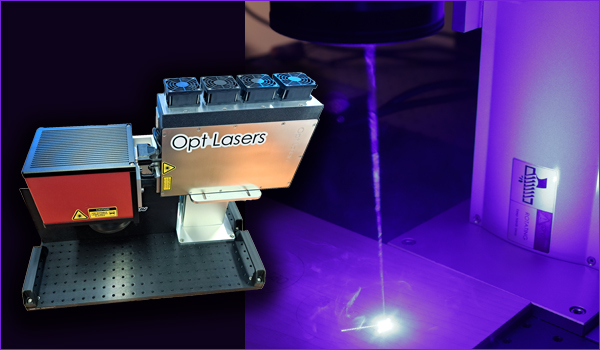

Blue laser technology is constantly evolving and the use of blue laser sources in manufacturing systems provides significant advantages over conventional engraving and cutting machinery as well as CO2 and fibre laser sources alike. Opt Lasers is at the forefront of this Blue Revolution, having taken a significant step forward with the release of blue galvo laser marking systems. Their newly introduced blue galvo laser systems have garnered significant attention, complementing their existing range of laser heads.

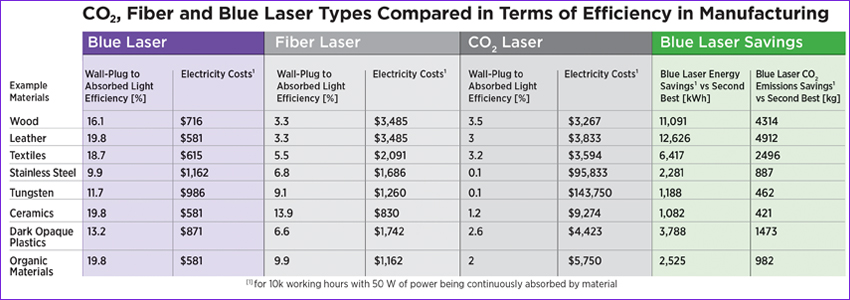

With higher laser absorption rates compared to fibre and CO2 lasers, as well as remarkably 4-5 times lower power consumption than CO2 options, Opt Lasers’ blue laser systems provide unparalleled process efficiency and precision at an affordable price. In addition, recently showcased at the Ligna 2023 trade fair on Felder Group’s Hammer CNC machine, the XT-50 laser head demonstrates Opt Lasers’ commitment to pushing the boundaries of blue laser technology. The Ultra-HD XT-50 laser head is so precise that even if the laser beam was focused to a smaller laser spot, the human eye would not notice the difference in the laser engraving and cutting precision. Alternatively, XT-50 is also able to engrave a 2 mm (0.079 inch) thick line by using the beam offset.

Rethinking manufacturing: The blue laser phenomenon

Blue lasers have emerged as a game-changer in the manufacturing industry, offering a host of benefits, across various applications, that add value to products, or streamline production processes while reducing costs.

Traditional options and CO2 lasers are now considered outdated, and fibre lasers are expensive while often performing worse than blue solutions. Blue laser systems provide higher absorption rates in manufacturing materials compared to other lasers. Another key advantage of Opt Lasers’ blue laser systems is their significantly lower electrical power consumption. Compared to conventional CO2 laser systems, blue laser systems consume 4-5 times less power.

This translates to greatly reduced operational costs and a greener and more precise approach to manufacturing, enabling manufacturers to achieve exceptional results in a shorter timeframe.

The incorporation of Galvo technology eliminates the need for physical movement of the laser source during engraving, cutting or processing. This allows Blue Galvo Lasers to achieve speeds 4-20+ times faster than blue laser heads, reaching for example 0.5 m/s (1.64 inch/s) or 2 m/s (6.56 inch/s) and higher.

Applications

Blue lasers find extensive applications across multiple industries. Whether it’s engraving metals and ceramics or cutting and engraving wood, fabrics, textiles, leather, and dark opaque plastics, Opt Lasers’ blue laser systems deliver outstanding performance.

In woodworking, blue galvo laser engravers offer exceptional capabilities for tasks like pallet engraving, ageing, blackening, and restructuring, as well as marking wood products. For instance, blue galvo lasers are an ideal choice for rapid and efficient EPAL branding of pallets.

In metalworking, blue lasers can process metals such as stainless steel, tool steel, Titanium, Tungsten Carbide, or Tungsten. They can be used for welding, burning, sintering, cladding, melting or metal hardening. Moreover, blue lasers excel in micro-welding copper, micro-soldering, soldering as well as welding metals or plastics together.

Blue lasers also offer an organic and pesticide-free solution for weed removal, ensuring a more environmentally friendly approach. This has been demonstrated by Weedbot’s automated precision farming solutions for the agriculture industry.

Since laser heads offer super-precise performance with focused beam spot sizes as small as 5 microns, it also makes them ideal for microscopy devices. In addition, they can also be used for specimen heat treatment or cutting of organic tissues under a microscope.

Applications research

Opt Lasers goes beyond offering cutting-edge laser technology. Opt Lasers sets itself apart by offering material testing services to help manufacturers assess the suitability and benefits of blue laser systems for their specific applications before making a purchase. By conducting thorough tests, Opt Lasers enables customers to make informed decisions and select the most suitable laser system for their individual needs.

Additionally, Opt Lasers’ commitment to research and development enables them to discover new and intriguing laser applications and unlock previously untapped opportunities. For instance, in the laser processing of technical ceramics like Alumina (Al2O3), Boron Carbide (B4C), Silicon Carbide (Carborundum, SiC), Titanium Diboride (TiB2) and Tungsten Carbide (WC), blue lasers show exponential increases in absorption compared to other laser sources. These technical ceramics are used in tank armour, anti-ballistic armour plating, bulletproof vests, penetration shells and artillery.

For instance, 6H-SiC silicon carbide at a high temperature (near its melting point) absorbs a blue laser over 15x more efficiently than an 808 nm fibre laser and 6000x more efficiently than a CO2 laser. For Titanium Diboride at room temperature, one could expect 25% higher blue laser absorption than for an 808 nm fibre laser and 200% higher than for a CO2 laser. Absorption on Boron Carbide shows similar values. On the other hand, melted Alumina absorbs blue laser beams 400%-1400% more efficiently than 0.8-1.1 µm fibre lasers, while room temperature blue laser absorption is 40-50% higher.

The advantages of blue laser systems extend beyond industrial applications. In surgical procedures, blue lasers exhibit higher absorption rates in tissues, making them optimal for precise tissue cutting or wound sealing. The potential for blue lasers to revolutionize surgical procedures highlights their versatility and potential impact across various fields. Additionally, blue lasers show promise for oxygen-free charring of wood for fuel production.

Production lines, robot arms and scalability

Mounting blue laser heads or blue Galvo laser systems onto production machines or robot arms is seamless due to their lightweight and compact design. Their small footprint allows for easy integration into existing manufacturing processes without the need for extensive modifications or occupying excessive space. This versatility enables manufacturers to optimize their production lines and adapt to evolving demands with agility.

Instead of a single CO2 laser machine, one can employ 100 blue laser heads (or 10 blue galvo laser systems) from Opt Lasers, achieving faster speeds and higher electrical efficiency. Despite occupying the same space as a single CO2 laser, multiple laser heads can provide significant advantages. Alternatively, as Blue Galvo Laser systems can achieve speeds 5-20 times faster than blue laser heads, it makes them ideal for high-volume production lines, where time-saving is crucial. Ultimately, the perfect laser system depends on the customer’s specific needs.

Blue laser products range

Opt Lasers is a leading provider of innovative laser solutions, specializing in blue laser technology that revolutionizes manufacturing processes. Their product lineup includes a range of laser heads, blue galvo laser modules, and Galvo laser systems, designed to meet diverse application requirements and deliver exceptional performance.

Blue Galvo Laser systems with FS-30W and FS-50W galvo laser modules are commonly ordered options, offering exceptional performance with square spot sizes as small as 100 microns and 130 microns, respectively. Blue Galvo Laser Systems are the best option for high-speed engraving or marking as well as cutting thin materials up to 2 mm.

Opt Lasers can also design and manufacture laser modules with higher optical power, reaching hundreds of Watts. Moreover, they can also customize laser systems according to specific requirements, ensuring optimal performance and versatility for each customer’s unique needs. Opt Lasers’ galvo laser sources are also available on their own if a manufacturer prefers to build their own galvo laser system.

On the other hand, Opt Lasers’ laser heads are ideal for more precise laser engraving, cutting thicker materials, as well as for applications that require high laser power density. Laser heads are available with different laser powers as well as different optical power densities and laser spot sizes. The two most interesting choices are PLH3D-6W-XT-50 and PLH3D-30W laser heads. XT-50 features a 50 µm square focused laser spot size and an optical power density of 2400 kW/cm². PLH3D-30W on the other hand has a 200 µm wide laser spot and 3200 kW/cm² power density.

Opt Lasers’ laser heads are available in kits for fast-track integration with virtually any CNC machine or CNC system, making them easily adaptable to existing production setups. Opt Lasers is also capable of manufacturing custom laser heads, tailored to meet specific manufacturing needs. This includes laser heads with focused beam spot sizes as small as 5 microns, catering to specialized applications such as microscopy.

Final words

In conclusion, Opt Lasers’ state-of-the-art blue laser heads and Galvo laser systems represent a significant leap forward in manufacturing technology. At the same time, integrating blue lasers into manufacturing lines or products is a strategic move that provides a significant competitive advantage.

The superior absorption rates, lower power consumption, cost reductions, scalability, versatility, precision and pure processing speed of blue laser solutions offer significant advantages over both traditional manufacturing technology as well as other laser solutions.

By embracing the power of blue lasers, manufacturers can unlock new levels of efficiency and stay at the forefront of the ever-evolving manufacturing landscape before competitors seize the opportunity. With Opt Lasers as a trusted partner, manufacturers can expect not only cutting-edge technology but also exceptional customer support. Opt Lasers’ team of experts is dedicated to assisting customers in finding the right solution and maximizing the benefits of blue laser technology.

The Blue Revolution is here, and Opt Lasers is empowering manufacturers to unlock their full potential.

Advertisement

- CME hopeful for B.C. port strike resolution; calls for federal government to hold parties accountable

- Increased robotics adoption accelerates machine vision systems market: ARC Advisory Group