Hexagon debuts carbon Composite Inspection System

September 9, 2017

By Manufacturing AUTOMATION

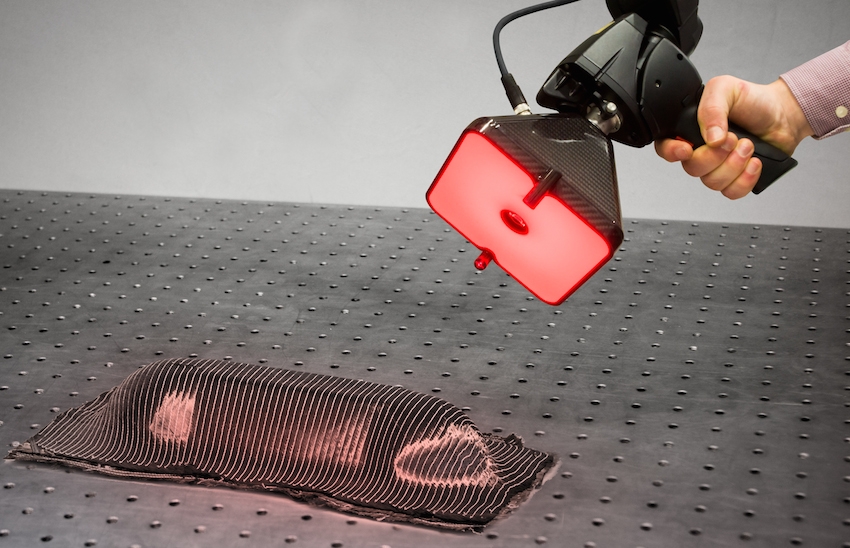

Sep. 8, 2017 – Hexagon Manufacturing Intelligence has introduced a new carbon Composite Inspection System, specifically designed for the aerospace industry.

Based on Apodius 3D technology, the new system promises to deliver advanced inspection and analysis of lightweight carbon-fibre components at an “unprecedented level of speed and detail.” The solution automates the manual visual inspection process of carbon composites, and helps to reduce component weight and material usage, notes the company, adding that the system is comprised of a portable ROMER Absolute Arm with Integrated Scanner, the HP-C-V3D Apodius Vision Sensor camera-based scanning hardware, and the custom-built Apodius Explorer 3D real-time software package. The ROMER Absolute Arm SI acts as a global reference system for data collected by the Composite Inspection System, addressing a range of industries including aerospace, automotive, marine, electronics and more. This solution boasts high-definition fibre orientation and geometry measurement, as well as complete three-dimensional model creation and analysis. Operators can perform actual-to-target value comparison and detect, document and classify previously difficult to define composite production errors, says the company.

Advertisement

- Schunk EGM-M gripper boasts high holding forces in small spaces

- Cognex introduces second-gen In-Sight 7000 vision system