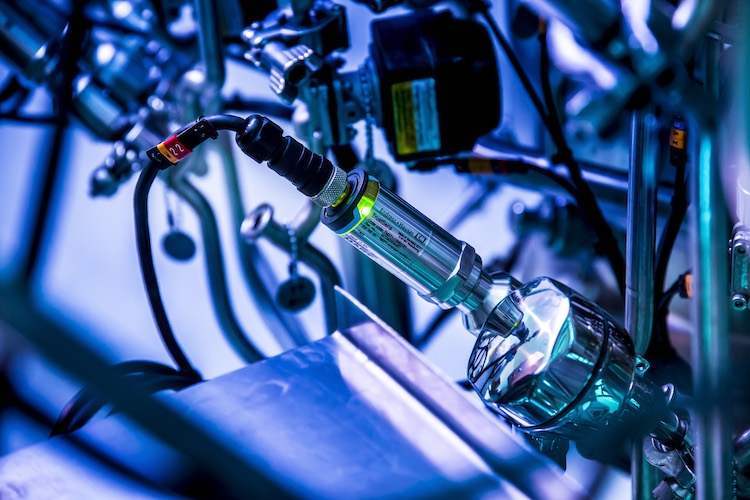

Endress+Hauser debuts TrustSens Self-Calibrating RTD temperature sensor

November 27, 2017

By Manufacturing AUTOMATION

Nov. 27, 2017 – Endress+Hauser has introduced what it says is the world’s first self-calibrating temperature sensor, the iTHERM TrustSens hygienic RTD.

Traditionally, calibration cycles for standard temperature sensors in critical service are every six to twelve months. This leaves the potential for undetected drift in the sensor between cycles. Such undected drift could lead to product quality issues or even a complete loss of the production run. TrustSens’ self-calibration process functions in situ and provides the documentation to meet the conformance requirements for various regulatory agencies. With TrustSens, the temperature sensor is calibrated after every Sterilize in Place (SIP) process cycle, and works to eliminate the risk of an undetected calibration drift and the risk of bad batches. It also reduces the need for frequent calibrations by verifying the sensor is working as designed in between manual calibration cycles, notes the company. TrustSens has a built-in ceramic reference based on the Curie Point of the reference material; that is, the temperature at which its ferromagnetic properties abruptly change. The change can be detected electronically. For applications using SIP operations — where steam at 121 degrees C is used to sterilize equipment — TrustSens uses a reference material with a Curie Point of 118 degrees C. The sensor is available with a variety of hygienic process connections, such as 1/2 to 3-in. Tri-Clamp and Varivent. It can also be configured for direct immersion measurement or with a protective thermowell for easy removal from the process.

Advertisement

- igus develops honeycomb strain relief CFU for e-chains

- In a time of robots, educators must invest in emotional labour