April 17, 2024

Nominate young leaders today for our annual ‘Top 10 Under 40’! Deadline is April 26

March 11, 2024

Defending the factory floor

February 20, 2024

Meet the speakers for Advance: Women in Manufacturing 2024

April 25, 2024

Universal Robots integrates Standard Robot Command Interface into its softwareApril 22, 2024

Schunk receives the 2024 Hermes Award at Hannover Messe

Advertisement

-

Sep

09

2024IMTS 2024

2301 S Martin Luther King Dr, Chicago, IL 60616, United States -

Jun

18

2024MMTS 2024

201 Av. Viger O Montréal, QC H2Z 1X7 -

Jun

11

2024ISA Calgary Show

20 Roundup Way SE, Calgary, AB T2G 2W1 -

May

15

2024SmartMTX 2024

Westerner Park, Red Deer, AB

News you can use from leading suppliers

Products

Products

Powered by FRASERS

Add Your Product

Operated Solenoid Valves

Process Instruments and Components Inc

Solenoid operated valves are available from experienced Canadian distributor Process Instruments and Components Inc. We have been serving a variety of indu...

Static Control Systems

Exair LLC

Static electricity discharges can be annoying and frustrating in your home. In a factory, however, static shocks transform into potential threats to produc...

Temperature Controllers

Mod-Tronic Instruments Ltd.

A complete selection of temperature controllers is available from Mod-Tronic Instruments Ltd. These products are supplied by renowned manufacturers such as...

Railcar Unloaders

Pneuveyor Systems International Ltd.

Pneyveyor Systems International Ltd. can provide railcar unloaders of many types to suit your specific requirements. Our products range from portable units...

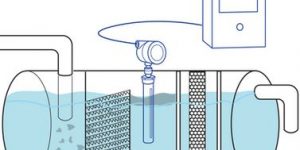

Oil Water Separators

Arjay Engineering Ltd.

Arjay Engineering Ltd. offers a variety of monitors and controls for use with oil/water separators. They can provide continuous monitoring of the oil/water...

Plastic Gasket

M M Plastic (Mfg) Co Inc

Plastic gaskets from M M Plastics provide excellent integrity and performance in a wide range of applications. In many industries, environmental factors ca...